What is Waste Heat Recovery and How Does It Benefit Energy Efficiency

Waste heat recovery (WHR) is an essential process that captures excess thermal energy from industrial operations and converts it into usable energy, significantly enhancing overall energy efficiency. As emphasized by Dr. Emily C. Reynolds, a renowned expert in energy systems, "Embracing waste heat recovery not only reduces energy consumption but also contributes to sustainable industrial practices." In an era where energy conservation is paramount, the importance of converting waste heat into valuable resources cannot be overstated.

The principles of waste heat recovery are rooted in the pursuit of efficiency; industries can minimize their carbon footprint while generating additional power often from emissions that would otherwise go unused. WHR systems pave the way for a more sustainable future, utilizing innovative technologies that ensure industries become less reliant on traditional energy sources. By acknowledging the potential of waste heat recovery, businesses can transform their energy strategies, ultimately leading to cost savings and reduced environmental impact.

In conclusion, waste heat recovery represents a critical step towards optimizing energy use in various sectors. The ongoing advancements and applications in this field not only underscore the significant benefits for energy efficiency but also highlight a pathway through which industries can align with global sustainability goals.

Understanding Waste Heat Recovery Systems

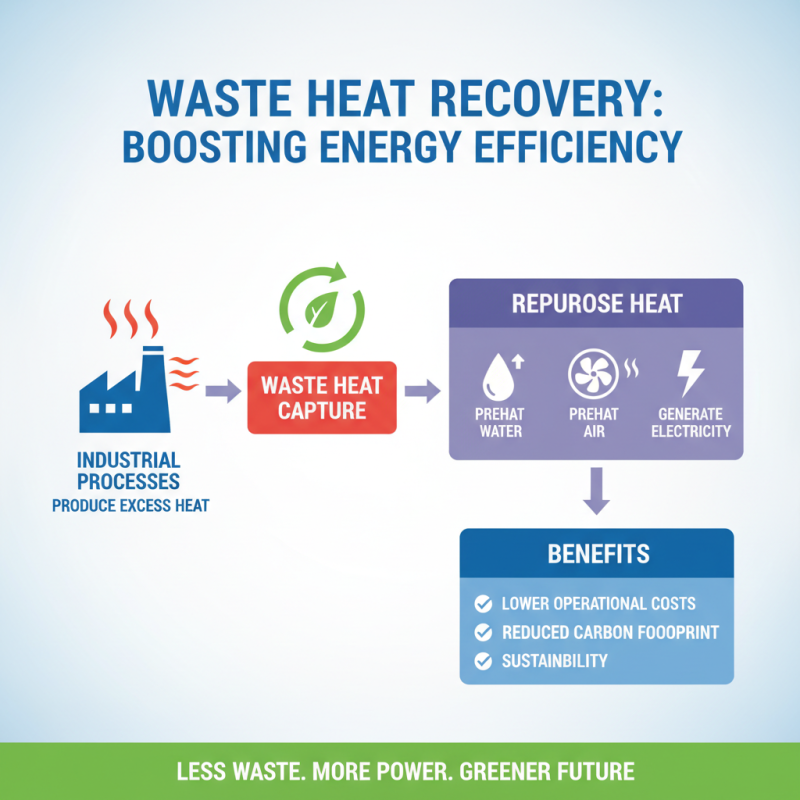

Waste heat recovery systems play a crucial role in enhancing energy efficiency across various industries. These systems capture excess thermal energy produced during industrial processes, which would otherwise be released into the environment as waste. By repurposing this heat for other applications, such as preheating air or water, or generating electricity, waste heat recovery significantly reduces the overall energy demand of a facility. This process not only leads to lower operational costs but also minimizes the carbon footprint associated with energy production, promoting sustainable practices.

The design of waste heat recovery systems can vary widely depending on the specific needs and operations of a facility. Common technologies include heat exchangers, organic Rankine cycle systems, and thermoelectric generators, each tailored to effectively harness waste heat from different sources like exhaust gases or heated surfaces. The effectiveness of these systems is contingent upon careful analysis of temperature levels and flow rates, allowing for optimal integration into existing operations. As industries continue to seek ways to improve energy efficiency, the adoption of waste heat recovery systems presents a viable solution for reducing energy consumption and enhancing overall productivity.

The Science Behind Waste Heat Generation

Waste heat generation is a prevalent phenomenon across various industrial processes, where heat that is produced as a byproduct is often released into the atmosphere without being utilized. According to the U.S. Department of Energy, approximately 20-50% of the energy consumed in industrial processes is ultimately lost as waste heat. This substantial inefficiency underscores the importance of understanding the science behind waste heat generation and its potential recovery.

The potential of waste heat recovery is vast, as highlighted by various case studies that reveal energy savings ranging from 10% to 30% in manufacturing sectors that have integrated heat recovery systems. This advancement not only reduces operational costs but also contributes to lowering greenhouse gas emissions, promoting a more sustainable energy landscape. As industries continue to evolve towards greater energy efficiency, harnessing waste heat remains a fundamental strategy in minimizing energy waste and enhancing productivity.

Methods and Technologies for Waste Heat Recovery

Waste heat recovery involves capturing and utilizing excess thermal energy generated during industrial processes, power generation, and other applications. The primary methods employed for this purpose include heat exchangers, heat recovery steam generators (HRSG), and thermoelectric generators. These technologies are designed to reclaim waste heat from exhaust gases, cooling systems, and other sources, converting it into useful energy or improving the overall energy efficiency of processes.

One of the most common techniques is the use of heat exchangers, which transfer heat from hot exhaust gases to a fluid, often water or oil, which can then be used to produce steam or preheat incoming fluids. This not only enhances thermal efficiency but also reduces fuel consumption and emissions. Another effective method is the installation of HRSGs in combined cycle power plants, which capture high-temperature exhaust from gas turbines to generate additional electricity. Additionally, thermoelectric generators utilize temperature differences to convert waste heat directly into electrical energy, providing a versatile solution for recovery where traditional methods may not be feasible.

Each of these technologies plays a crucial role in mitigating energy loss and optimizing resource utilization in various industrial and commercial settings.

Benefits of Waste Heat Recovery for Energy Efficiency

Waste heat recovery (WHR) is a cutting-edge technology designed to capture and repurpose waste heat generated in various industrial processes, thus significantly enhancing energy efficiency. According to a report by the International Energy Agency (IEA), approximately 50% of the energy consumed in industrial processes is lost as waste heat. By implementing WHR systems, industries can reclaim a portion of this lost energy, leading to reduced operational costs and lower greenhouse gas emissions. The U.S. Department of Energy estimates that widespread adoption of WHR could improve energy efficiency in industrial sectors by up to 20%, translating to savings of billions of dollars annually.

The benefits of waste heat recovery extend beyond mere cost cutting; they play a crucial role in promoting sustainable practices. A study conducted by the American Institute of Chemical Engineers (AIChE) found that capturing and reusing waste heat can reduce energy consumption by about 30% in specific scenarios, like power generation and manufacturing. This not only lowers the environmental footprint of industrial operations but also contributes to energy independence as less energy is sourced from external grids. WHR systems can vary, from simple heat exchangers to complex combined heat and power (CHP) systems, showcasing their adaptability to different industrial needs and further underlining their potential in boosting overall energy efficiency.

Applications of Waste Heat Recovery in Various Industries

Waste heat recovery (WHR) is an essential technology that plays a pivotal role in enhancing energy efficiency across various industries. In manufacturing, for example, a significant portion of energy used in processes is often lost as waste heat. According to the U.S. Department of Energy, up to 50% of energy consumed in industrial processes is dissipated as heat. Industries such as steel production, cement manufacturing, and chemical processing are increasingly adopting WHR systems to capture this heat and repurpose it for heating water or generating steam. This not only reduces energy consumption but also lowers greenhouse gas emissions, contributing to sustainability efforts.

In the power generation sector, WHR systems are utilized to capture excess heat from turbine exhausts, improving the overall thermal efficiency of power plants. A report from the International Energy Agency (IEA) indicates that employing waste heat recovery can result in efficiency improvements of up to 20% in existing plants. Additionally, the food and beverage industry employs WHR techniques to reclaim heat generated during cooking processes, which can be redirected to preheat incoming water or sanitize equipment. By leveraging WHR, companies can significantly reduce operational costs while adhering to increasingly stringent environmental regulations aimed at curbing energy waste and emissions.

Waste Heat Recovery Applications and Their Energy Savings

Waste heat recovery (WHR) systems help various industries capture excess heat that is otherwise wasted. The chart above illustrates the energy savings (in GWh per year) achieved through waste heat recovery across different sectors, highlighting the potential of WHR in improving energy efficiency.

Related Posts

-

Top 5 Waste Heat Recovery Technologies: Maximizing Efficiency with a 20% Energy Savings Potential

-

What is a Spa Heat Pump and How Does It Efficiently Heat Your Spa

-

Top 10 Spa Heat Pumps for Energy Efficiency and Optimal Performance

-

10 Tips for Choosing the Best CO2 Heat Pump for Your Home

-

10 Best Heat Pumps for Efficient Heating in Colorado's Climate

-

Top 10 Energy Efficient Heating Solutions for 2025: Save Money & Reduce Emissions