Heat pump technology is revolutionizing the way we approach heating and cooling systems by using renewable energy and waste heat. Heat pumps work by transferring heat from a low-temperature source to provide higher-temperature heat, all through a proven vapor-compression thermodynamic cycle. Heat pumps are becoming a central part of the global energy transition, as both industries and homes seek sustainable solutions to decarbonize heat production, which is responsible for a significant portion of global energy consumption and carbon emissions.

The industrial sector accounts for one-third of global CO2 emissions, with heating processes contributing over 20% of these emissions, primarily due to reliance on fossil fuels such as natural gas, coal, and oil. Industrial heat pumps, which use electricity and sources like seawater or excess heat, can deliver three to five times more heat energy per unit of electricity than traditional systems. With the ability to operate at temperatures up to 200ºC and large capacities, they offer a cost-effective and environmentally friendly alternative, especially as gas prices rise.

In this article, we will focus on the following key insights:

- How heat pumps work

- Key components of a heat pump system

- Advantages of using heat pumps

- Different types of heat pump technologies

- Exergy industrial heat pumps

1. How does a Heat Pump System work?

Heat pumps are highly efficient and can be powered entirely by renewable energy, utilizing electricity along with heat from air, water, and ground sources, as well as excess energy from industrial processes and building exhaust air.

But how does a Heat Pump System work?

A heat pump works by utilizing the compression refrigeration cycle, where a transfer fluid, or refrigerant, moves heat from a low-temperature source to a higher-temperature sink. The process begins in the evaporator, where the refrigerant absorbs heat from the heat source and evaporates. This vaporized refrigerant is then compressed using mechanical energy provided by an electric motor, raising both its pressure and temperature.

At high pressure and temperature, the refrigerant vapor flows into the condenser. Here, the heat is transferred to the distribution medium, such as air or water, and the refrigerant vapor is cooled, condensing back into a liquid. This liquid, still under high pressure, passes through an expansion valve, where its pressure and temperature are reduced, allowing it to return to the evaporator.

This cycle continues in a closed loop, efficiently transferring heat in both heating and cooling modes. The system is often hermetically sealed to ensure smooth, continuous operation, providing energy-efficient heat transfer across various applications.

2. Heat Pump system components

The performance of a heat pump is largely influenced by its core components, the compressor and heat exchangers (condenser and evaporator). Among these, the compressor is considered the most crucial, as it directly impacts the refrigerant flow rate and the efficiency of the compression process. Essentially, the compressor determines how much heat energy can be absorbed by the refrigerant and, in turn, how effectively the pump can adjust temperatures. Due to their complexity, compressors represent a substantial share of the total hardware capital costs of a heat pump and often contain valuable intellectual property. While the compressor plays a central role, other components, particularly the heat exchangers, are also vital to overall efficiency. At Exergy, these exchangers are a well-established technology and can be tailored to meet the specific requirements of large-scale heat pump applications.

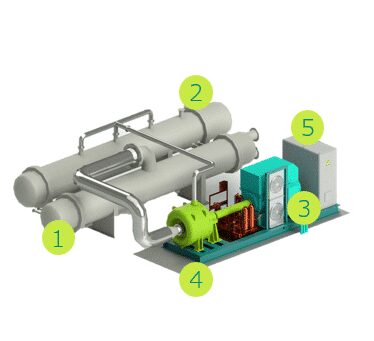

Exergy provides a variety of heat pumps, designing and manufacturing all core components in-house while sourcing other parts from trusted suppliers. Let’s now take a closer look at each individual component:

Static Components

- Shell-and-tube (S&T) Evaporator (1): This component is internally designed by Exergy to absorb heat from the surrounding environment and vaporize the refrigerant.

- Shell-and-tube (S&T) Condenser (2): Also designed by Exergy, the condenser is responsible for releasing the heat from the refrigerant to the heat user or heat sink.

- Internal Heat Exchanger (IHX or Recuperator): This component heats the vapor from the evaporator by using the liquid condensate from the condenser. It can be installed when internal heat recovery is advantageous, helping to improve efficiency.

- Shell-and-tube (S&T) Subcooler: Designed by Exergy, the subcooler is beneficial for improving the coefficient of performance (COP) and may be installed in both Heat Pumps Series, dual stage and single stage, when the heat sink conditions make it advantageous.

- Control & expansion valves: These are typically air or electrically actuated and are crucial for regulating the flow of refrigerant, maintaining optimal performance throughout the cycle.

- Electrical & automation panels (5): Designed in-house by Exergy, these panels incorporate the company’s proprietary software to efficiently manage system operations. Built with high-quality components and rigorous engineering standards, they enhance safety and reliability by ensuring precise control, minimizing operational risks, and optimizing performance. Their robust design also improves system durability and resilience, providing a dependable solution for long-term operation.

Rotating Components

- Electric Motor (3): Typically, a Direct-On-Line (DOL) air-cooled motor is used. However, for smaller applications, an air-to-water cooled motor with a Variable Frequency Drive (VFD) may be utilized to enhance efficiency and control.

- Compressor (4): Two compressor types are available, selected based on the heating capacity, efficiency, and cost targets of the system.

a. The Turbo-compressor features an Inlet Guide Vanes (IGV) system for effective capacity control, with either an integrally geared or direct drive mechanism for high efficiency.

b. The Screw-compressor is supplied by industry-trusted suppliers and is typically semi-hermetic, offering reliable performance for a range of applications.

3. Advantages of Heat Pumps

Heat pumps offer a highly efficient alternative to traditional heating systems, making them an attractive choice for both residential and industrial applications. While heat pump technology is not new, its potential, particularly in industrial settings, is being increasingly recognized. Factors such as the global push for decarbonization, the electrification of heat, economic considerations, and government incentives are contributing to a surge in market growth for industrial heat pumps, with annual growth expected to exceed 15% until 2030. In Europe, industrial heat pumps with a combined capacity of 15 GW could be implemented in approximately 3,000 installations across industries like chemicals, paper, and food, significantly driving their widespread adoption. (Source: McKinsey & Company)

Industrial heat pumps are particularly well-suited to meet the growing demand for sustainable heat generation in industrial processes and district heating networks, offering many advantages:

- Heat pumps provide much more heat for the same amount of electricity compared to direct electric heating

- Their lower electricity consumption means reduced operational costs than direct electric heating

- Heat pumps efficiently exploit low-temperature waste heat sources, further enhancing their energy-saving capabilities

- Heat pumps come with simple operation and low maintenance requirements

- Heat pumps are also highly effective for heating and cooling, and a single unit can provide both services. This dual capability creates significant opportunities for optimized business models

By combining heating and cooling, synergies can be achieved between different sectors. For example, data centers can be linked to district heating networks, where heat pumps not only cool the data centers but also upcycle the waste heat to contribute to the district heating supply. This integrated approach maximizes the impact of the heat pump by efficiently circulating heat energy across both systems.

To explore more benefits and advantages of Exergy’s industrial heat pumps and discover how they can enhance your energy efficiency and sustainability, visit Exergy Industrial Heat Pumps page!

3.1 Why are Heat Pumps more efficient?

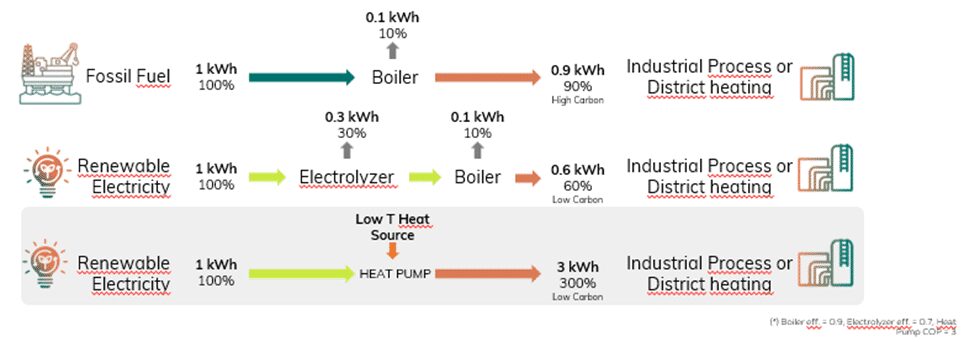

Heat pumps are currently the most advanced and efficient solution for producing heat in industrial settings and district heating systems, surpassing the limitations of natural gas boilers and electric boilers. The key advantage of heat pumps lies in their different operating principle: a heat pump does not generate heat, but rather transfers it, utilizing low-temperature thermal sources that would otherwise be wasted. This efficiency is made possible by a closed-loop thermodynamic cycle that takes advantage of the properties of natural or synthetic fluids, which change states (evaporate or condense) at different temperatures depending on the pressure they are under.

Unlike gas boilers, which burn fossil fuels to produce thermal energy, or electric boilers, which directly convert electricity into heat, heat pumps harness the energy already present in the air, water, or industrial process flows, “moving” and amplifying it through a relatively low electricity consumption. As a result, heat pumps can produce 2 to 5 units of heat for every unit of electrical energy used, significantly reducing consumption and eliminating emissions. Instead, when comparing an electric boiler generates approximately 1 unit of heat for every unit of electricity consumed, while a gas boiler produces around 0.9 units of heat for each unit of energy in the natural gas burned (with corresponding emissions released through the chimney).

4. What are the different technologies for heat pump

Heat pumps are available in various types, each tailored for specific applications, energy sources, and efficiency requirements. One widely used type is the VCC (Vapor Compression Cycle), which operates on a subcritical refrigeration cycle. Another category includes open-cycle heat pumps, such as MVR (Mechanical Vapor Recompression), which are designed to elevate steam to higher temperatures for industrial processes. Heat pumps can also be categorized by their energy source:

- Air-source heat pumps: These extract heat from the ambient air and are available in two configurations: air-to-water, which transfers heat to a water-based system for heating or process applications, and air-to-air, which distributes heat directly using fans. While commonly used in residential settings, industrial air-source heat pumps are adapted for larger-scale operations, such as space heating in warehouses or low-temperature process heating. However, their efficiency may be limited in colder climates or for high-temperature industrial needs.

- Ground-source heat pumps: These systems extract heat from the earth via buried ground loops filled with a heat transfer fluid. Industrial ground-source heat pumps are ideal for large-scale heating, cooling, and hot water production, leveraging the stable thermal energy stored underground. They are particularly suitable for facilities with ample land for ground loop installation and are often used in district heating systems or industrial complexes requiring consistent thermal energy.

- Water-source heat pumps: These systems utilize water as the heat source or sink, making them highly versatile for industrial applications. They can operate in closed-loop configurations, where a heat transfer fluid circulates through a heat exchanger, or in open-loop systems, which directly use water from sources such as rivers, lakes, aquifers, or the sea. Industrial water-source heat pumps are particularly effective for harnessing waste heat from cooling water in industrial processes, wastewater, or district heating networks. They are also well-suited for simultaneous heating and cooling applications, making them a robust solution for energy-intensive industries.

- When several heat generators are combined, this is called a hybrid system.

4.1 Industrial Heat Pumps Application

In industrial settings, heat pumps play a crucial role by recovering waste heat from sources like sewage water, geothermal energy, river and sea water, and even process steam. Industries with high energy demands, such as food and beverage, chemicals, and paper, can reduce emissions and energy costs by implementing heat pump systems. These technologies are also essential in district heating networks, helping reduce fossil fuel use and CO2 emissions in sectors like chemical processing, IT data centers, and utilities. Heat pumps have many other applications, some of these include the iron and steel industry, non-ferrous metals, non-metallic minerals, and pulp industries. They also provide energy efficient wood products, textile and leather manufacturing, and transport equipment, supporting sustainable operations.

5. Discover Exergy Industrial Heat Pump

Exergy is advancing its capabilities by offering innovative Vapor Compression Heat Pumps, called X-heat. These industrial heat pumps are available for both medium- and large-scale applications, providing efficient heat solutions across a wide temperature range, from conventional low temperatures (~50°C) to high temperatures exceeding 150°C.

The X-heat series includes systems for smaller industries (under 5 MWth) or combined with boilers, as well as larger industrial processes and district heating applications (up to 50 MWth). For smaller-scale applications, the systems utilize screw compressors, while turbo compressors are employed for larger-scale operations. Exergy’s heat pumps are engineered to maximize the Coefficient of Performance (COP), ensuring optimal efficiency by carefully selecting refrigerants and cycle configurations. The COP typically ranges from 2 to 5 in standard applications, depending on the heat source, sink temperature, refrigerant, and compressor design.

Exergy’s heat pumps are designed with sustainability in mind, using environment-friendly refrigerants with zero Ozone Depletion Potential and the lowest Global Warming Potential, prioritizing natural refrigerants like hydrocarbons when possible. These systems do not contain toxic or corrosive refrigerants, further supporting their environmentally friendly design.

Exergy’s systems are suitable for a wide range of industries, including steam production, and are particularly effective at providing high lift (over 80 K) to transform low-grade thermal power into valuable, low-carbon, high-temperature heat. The modular, compact configuration ensures easy installation, while the continuous development of Exergy’s technology pushes the boundaries of heat pump performance, offering high lift capabilities and superior efficiency across diverse applications.

Learn more about Exergy’s solution for industrial heat pumps.

Conclusion

In conclusion, heat pumps are a crucial component in the transition to a sustainable, zero-emission energy system by 2050. With a variety of solutions available to suit different needs and levels of modernization, they offer significant economic, environmental, and societal benefits. As technology continues to improve and efficiency increases, heat pumps will become even more cost-effective and widely applicable. By capturing and reusing excess heat, heat pumps contribute to a circular energy economy, enabling the shift from fossil fuels while promoting energy efficiency.

Looking for a customized solution? Contact us to find out how our industrial heat pumps can improve the efficiency of your plant!

Reach out now!